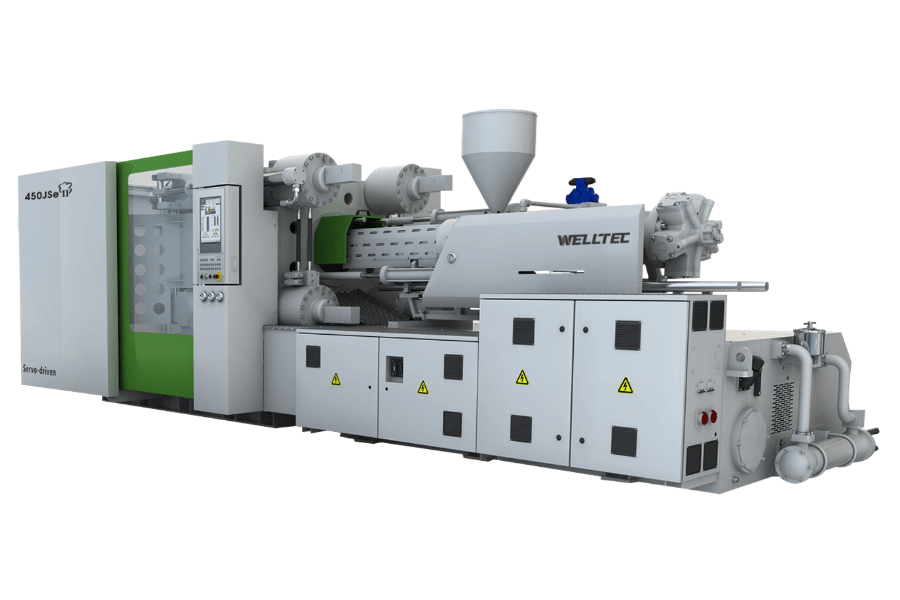

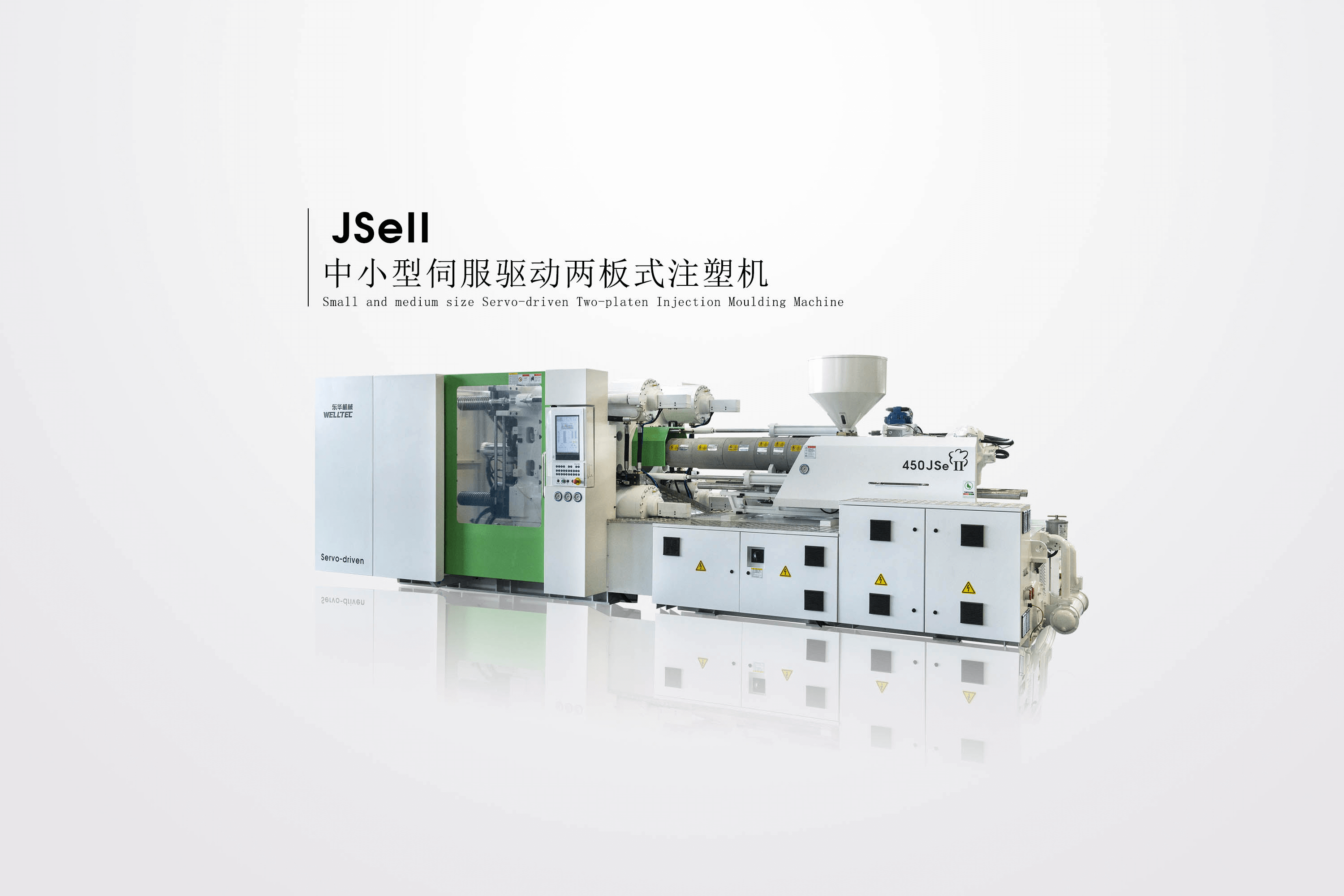

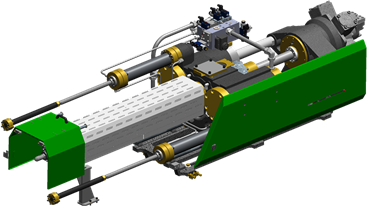

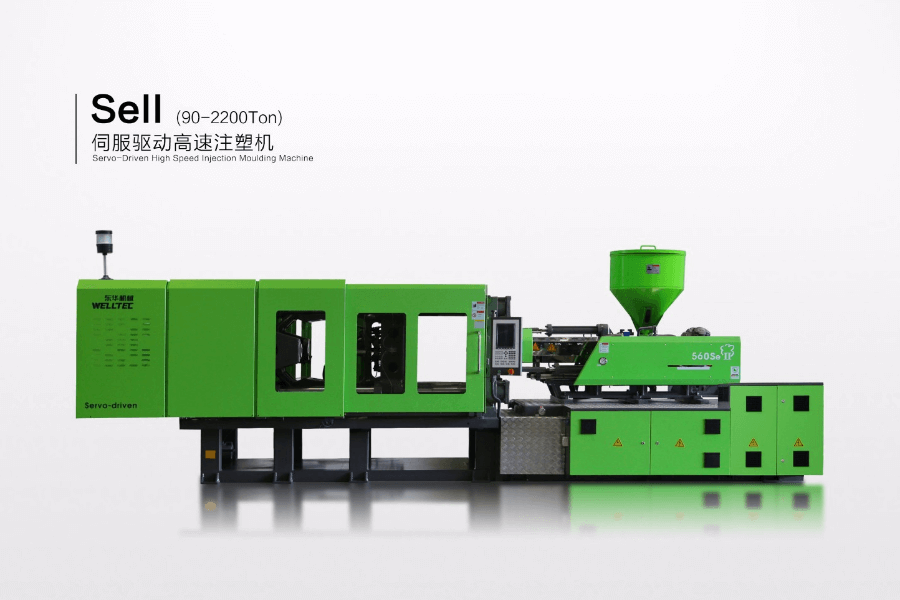

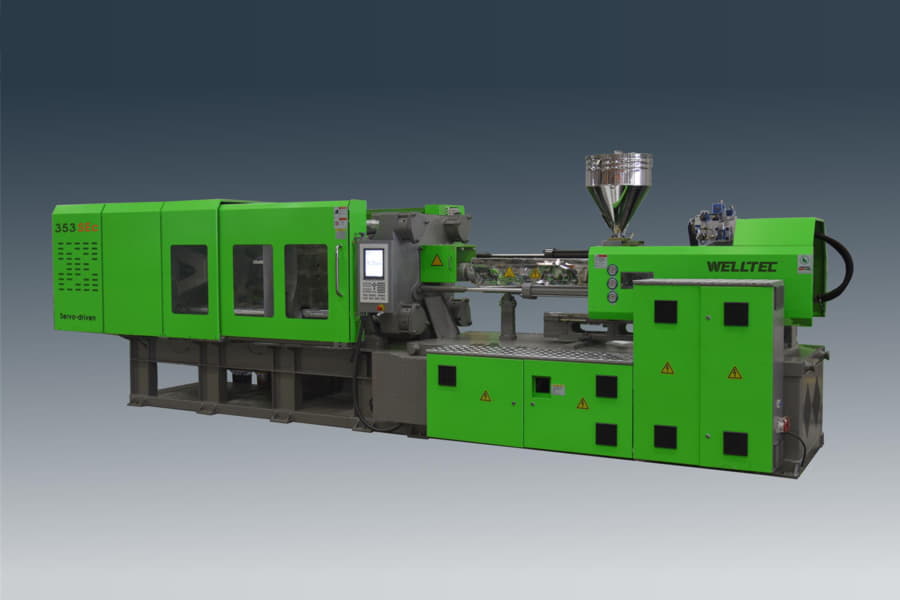

Clamping

- The advanced two-platen clamping unit has ccompact structure and less occupation area;

- The clamping cylinder installed on the fixed half ensures the template uniformly forced in clamping action;

- The clamping high-pressure cylinder stoke is short,and the speed of rising pressure is quick.The clamping force is proportional to the system pressure,which has good linearity.Real-time monitoring with pressure sensor,the repeatability of clamping force is very high;

- There is no friction between puller and movable half so that the service life is longer.And the diagonal layout of two hydraulic cylinders imprones the speed of opening and closing mould ;

- When using heavy mould,the long slipper can ensure the accuracy of template so that enhance the service life of mould;

- The puller adopts a synchronous brake device.And the brake cylinder with buffer function makes the cation more accurate,which can't generate hydraulic shock ;

- The humanized design of no upper beam safety door design and can be close to the machine operation,and convenient to take products

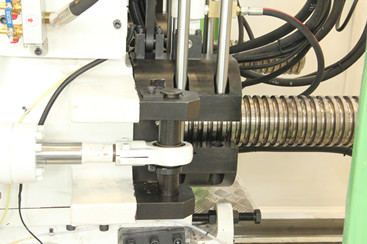

Injection Unit

- The diagonal layout of injection cylinder makes the overall injection unit more stable

Hydraulic unit

- It features with high-performance servo system,integreated oil circuit design,high efficiency output,fast response,energy-saving,stable and noise-reduction

Control unit

- European imported B&R professionally control system for injection moulding machine